Surface Engineering

Lafer S.p.A., established in 1986, is an ISO 9001, ISO 14001 e ISO 13485 certified company that provides PVD, PACVD, and DLC coating solutions to solve wear and friction problems on tools, molds, and components by applying the most advanced technologies worldwide.

Lafer S.p.A. continuously refines its base coatings by adapting them to the customer’s needs, creating specialized coatings optimized for dedicated applications.

20.000

pieces processed daily

13.000

sqm of area in a single location

Applications

Thanks to 21 state-of-the-art coating systems equipped with arc deposition technology, Magnetron Sputtering, PACVD and HiPIMS, Lafer is the Italian coating center with the highest concentration of coating systems. This allows for dedicated furnaces for each type of coating, product, or customer.

Applications

Thanks to 21 state-of-the-art coating systems equipped with arc deposition technology, Magnetron Sputtering, PACVD and HiPIMS, Lafer is the Italian coating center with the highest concentration of coating systems. This allows for dedicated furnaces for each type of coating, product, or customer.

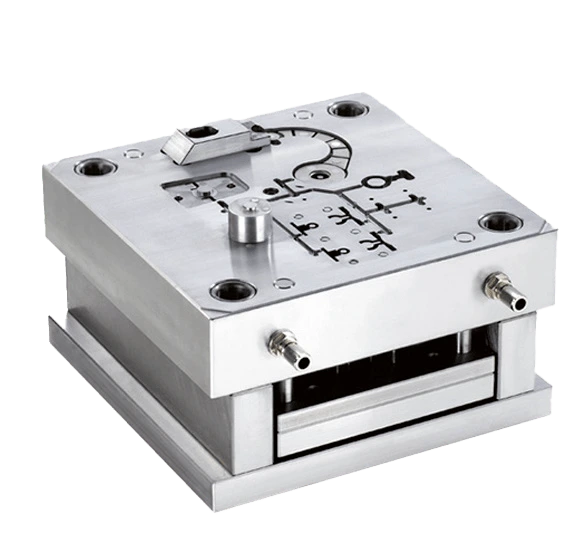

Tools

Lafer creates coatings for gear teeth, tools, and inserts using arc technology and Magnetron Sputtering and HiPIMS, offering the best solutions for reducing friction and operating temperatures, as well as for increasing cutting parameters.

24 H

SERVICE

DIRECT

CONTACT

24 H

SERVICE

LIVE

chat

Discover our Surface Engineering Services

The Lafer Method involves optimizing all variables that, along with dedicated coatings, contribute to achieving the customer’s desired outcome. To this end, Lafer has pioneered an innovative Surface Engineering department for the past 15 years. This department, continuously evolving with its R&D engineers, is committed to providing comprehensive consultancy services, focusing on customized processes.