Index

- Characteristics of HiPIMS Treatment

- Advantages: Why Choose HiPIMS Technology?

- Fields of Application

- Sustainability

1. Characteristics of HiPIMS Treatment

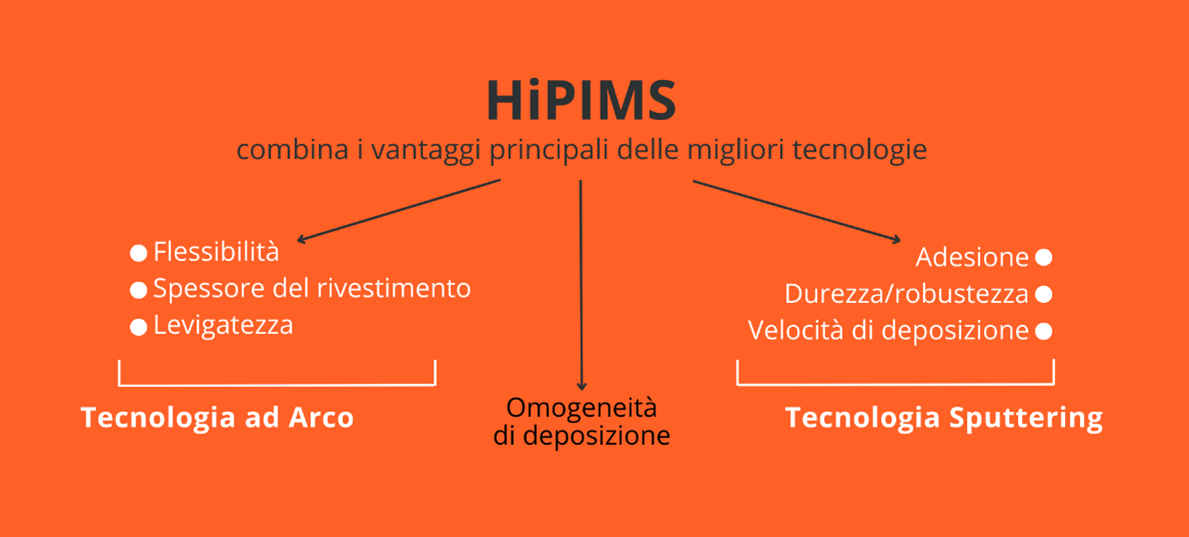

Like the DC Magnetron Sputtering process, HiPIMS technology allows for the deposition of coatings with extremely low surface roughness, free from droplets, and with reduced internal stress.

Tests demonstrate excellent coating adhesion, which is directly related to the high level of ionization during deposition. HiPIMS coatings are both hard and durable due to the dense and nearly amorphous structure of the film. A consistent and homogeneous coating thickness distribution around three-dimensional objects, such as the cutting edge of a tool, ensures excellent wear resistance.

This technology allows for a deposition rate that can reach up to 2 μm/h.

2. Advantages: Why Choose HiPIMS Technology?

- The technical characteristics of the HiPIMS process create a high-energy plasma that ionizes the deposited materials to extremely high levels. This results in a very dense and almost completely amorphous coating structure, with no preferred growth direction.

- The high ionization of metals ensures excellent adhesion, making these coatings suitable for machining the most challenging materials. The elevated ionization also makes the coating structure very dense and compact, and consequently, hard and durable. Coatings deposited with HiPIMS technology are extremely homogeneous, ensuring perfect and consistent coverage of tool cutting edges.

- HiPIMS is a sputtering process, which means it allows for an unlimited variety of materials in coating production, thanks to different combinations of elements from the periodic table. Additionally, HiPIMS technology enables the evaporation of even insulating materials.

- Suitable for micro-tools: defect-free and without antenna effects. The HiPIMS process can also be used with very small geometries, as it does not produce droplets and does not damage or round off cutting edges.

- Excellent productivity, with a deposition rate of up to 2 µm/h.

- HiPIMS significantly increases tool life compared to traditional coatings.

| ARC | CVD | HiPIMS | |

|---|---|---|---|

| Surface appearance | Medium roughness, droplets | High roughness, matte | Low roughness, glossy |

| Deposition temperature | 450°C | 1000°C | 450°C |

| Maximum coating thickness | 6µm | 10-15 µm | 12 µm |

| Residual coating stress | High compression | Tensile | Residual stress management for low compressive stress |

| Flexibility | Low | None | High (all materials, all substrates) |

| Suitable for micro-tools | No | No | Yes |

2.2 Sustainability

The high deposition rate allows for a reduction in the total coating process time, leading to energy savings.

Similarly, the use of high-performance coatings like HiPIMS enables an increase in cutting parameters, resulting in shorter production times while simultaneously extending the tool’s lifespan.