Lafer’s History

For over half a century, Lafer has been at the forefront of technological advancements in the coatings industry, embarking on its journey back in 1968 and evolving through innovations and strategic breakthroughs to become a leader in advanced coatings

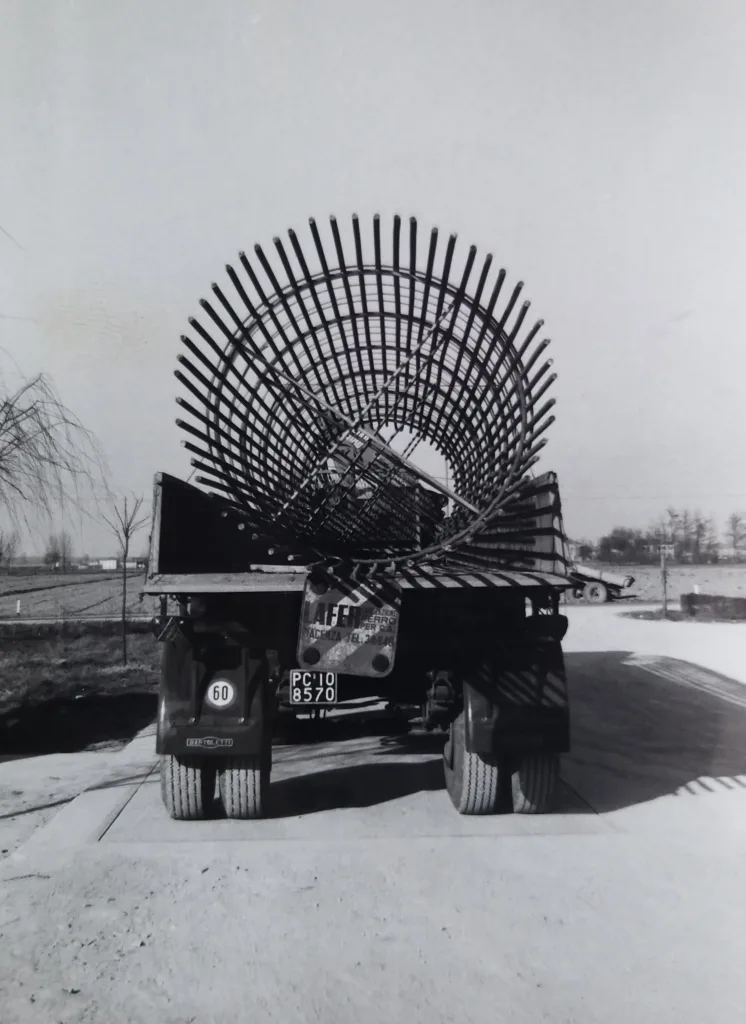

1968

In August 1968, on a hot afternoon, a man was planting stakes in a cornfield. The corn was tall, the heat stifling, and the few passersby wondered what that man was doing.

IT WAS THE BEGINNING OF LAFER. Giuseppe, Cesare, and Luigi Parenti.

1968

In the 1960s, the construction boom revolutionized the work of ironworkers on construction sites. The demand for iron for reinforced concrete had become too substantial, necessitating the concentration of such work within dedicated facilities.

Lafer Ferro was founded in August 1968 to meet this demand, and it remains active today in the processing and trading of all types of iron in the market.

1986

In the 1980s, the global market for heat treatments on steels began to develop.

Lafer decided to invest in this new market, and on August 11, 1986, the first Chemical Vapor Deposition (CVD) coating plant was put into operation.

This event officially marked the birth of Lafer Rivestimenti.

1991

The 1990s were a pivotal decade for Lafer.

The decision to pursue CVD coatings was abandoned in favor of Physical Vapor Deposition (PVD), a more versatile technology with extensive application potential.

With the commissioning of the second PVD plant, internal experiments began in 1995 on Titanium and Aluminum-based coatings, which proved to be a true revolution in the gear manufacturing sector.

1996

Another significant milestone was reached between 1996 and 1998 when Lafer decided to phase out all FREON-based washing systems in its cleaning department (chemical solvents used for cleaning parts emitting high levels of fluorinated gases) to embrace an eco-sustainable philosophy.

The existing plant was replaced with a fully automatic washing machine, pioneering the vacuum washing systems still used today, first installed in 2000.

1997

In 1997, the company participated in a European project that led to the patenting of a new internally developed and perfected coating, the Lafer Superlattice (SLC).

That same year, an automatic blasting plant was installed to remove bubbles from sharpened tools and residues from previous treatments. This marked the initial steps towards what would later be defined as the Lafer Method, involving the in-depth study of surfaces to be treated by the R&D department.

2000

By 2000, Lafer had 8 PVD plants in operation.

In less than 10 years, Lafer had already become one of the most advanced companies in the coating market. The expertise and preparation of the R&D department technicians enabled mastery of cutting-edge instruments and technologies to provide increasingly personalized service.

2008

Following the successes achieved with the Superlattice, in the early 2000s, new experiments began in the field of tribology to refine two carbon-based coatings.

Between 2008 and 2010, Lafer expanded its coatings portfolio with the introduction of CarbonLafer WC/C and DLC (Diamond Like Carbon).

2020

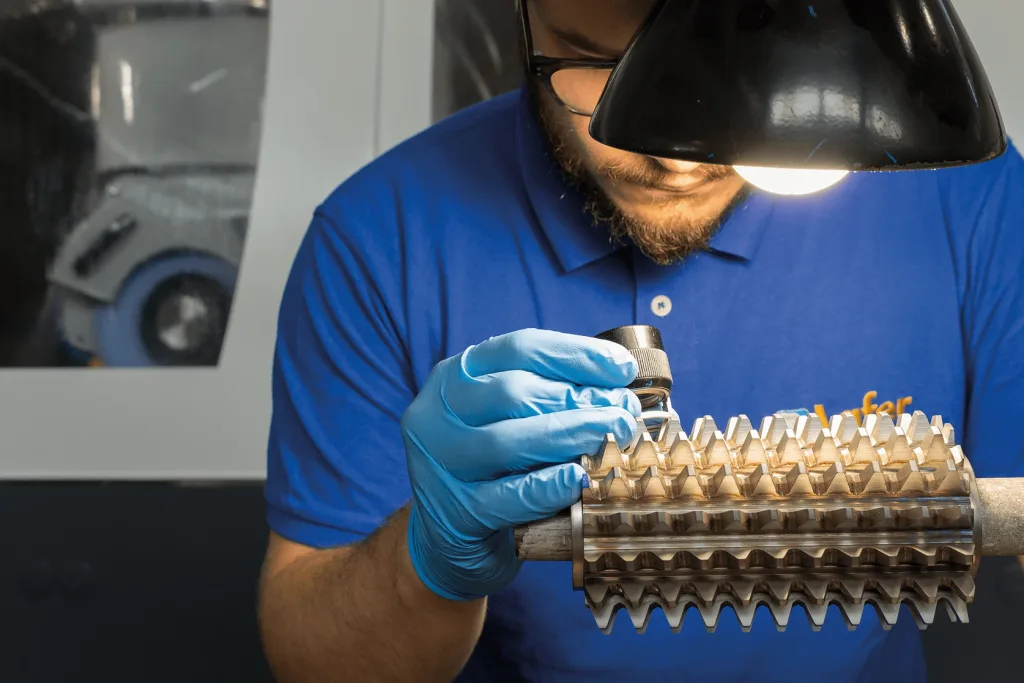

For over three decades, Lafer has provided excellent quality service derived from continuous improvement of its coatings portfolio.

The team of technicians and researchers has established a surface engineering department dedicated to ensuring ongoing specialization in studying all parameters influencing final performance.

With consistency and dedication, Lafer has developed three families of coatings based on a single common denominator.

Today, Lafer stands as the coating center with the highest concentration of coating plants.

2024